Design

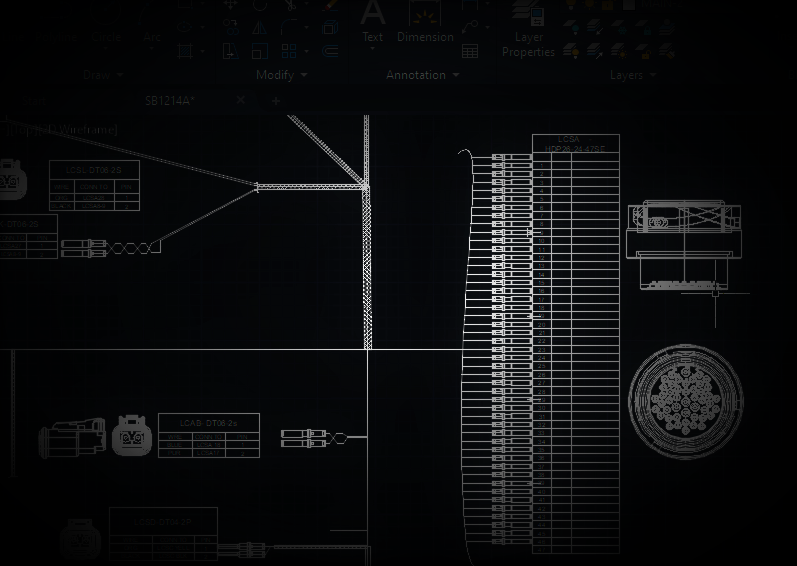

Cable harnesses are usually designed according to geometric and electrical requirements, a diagram is then provided (either on paper or on a monitor) for the assembly preparation and assembly.

To design, it is required to be familiar with required electrical specification to pick component accordingly.

To design, it is required to Be familiar with the environment and working condition in which you will place your cable assembly. The environment in which you will connect your cables determines the construction and materials involved in your customized assembly.

Prototyping, Building an early sample, model, or release of a product built to test a assembly.

Reverse Engineering,the process by which a cable/panel assembly is deconstructed to reveal its designs, architecture, or to extract knowledge from the object, a diagram is then provided (either on paper or on a monitor) for future assembly preparation and assembly.

Manufacturing

Specialized in the Production of Wire Harnesses- Harnesses

- Wire harness Assemblies

- Panel Wire Assemblies

- Control Panels-Boxes

- Fiber Optic Cables

- Mechanical Sub Assemblies

- Custom Cabinets

- Data Cables

- Temporary Assembly (sub-assembly)

- PCL wiring

- Battery and Power Cables